There are no products to list in this category.

Nails on strip

What are nails on strip?

Nails on strip, also called strip nails, are nails that are connected to each other in a strip. These are specially designed to be used in combination with a strip nail tacker. By using a nail-holding strip in combination with such a nailer, you can shoot nails several times in a row without having to constantly reload. Strip nails are widely used for fastening beams, planks and plates in various building constructions.

How do I choose the right nails on strip?

Each strip has specific properties that make them suitable for different purposes. But how do you choose the right one so that you can quickly continue with your projects?

Metal wire welded nails on strip

This is the most common way nails on strip appear. The nails are attached to a piece of metal wire. When the nail is driven into the material, a piece of the metal wire is also driven into the material. This means that with wire-welded strip nails you are left with no waste. Unfortunately, the wire-welded strips are not suitable for metal coating. That is why there are other ways to make nails on strips.

Paper tape tied nails

These nails are held in the strip by paper tape. This is an ecological and lightweight way to connect nails. However, keep in mind that they are more vulnerable to moisture and cracks in the strip.

Plastic bonded nails

This type of strip nail is held together by a plastic holder. This method of binding the strip is suitable for any type of material. However, it does leave plastic waste behind when the strip runs out. It also sometimes happens that nails fall out of the plastic strip, since they are only in a holder.

Different shapes of strip nails

The shape of the nail determines which bonding application it is suitable for. When purchasing nails, it is wise to pay attention to the following characteristics of the nail:

- Head

- Shaft

- Point

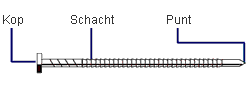

Head

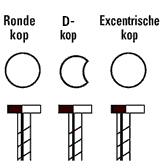

On the head of the nail is the part where the striking pin of a nailer strikes the material. There are three types of nail heads. Namely round, pinched or eccentric. As the name suggests, round head nails have a round head. Their shape resembles the nails that are available separately at the hardware store. Nails with a pinched or off-center head are also common in strip nails. The shanks of the nails are closer together. This way, more nails fit in the loading magazine. This ensures that you can shoot more often without having to reload.

Shaft

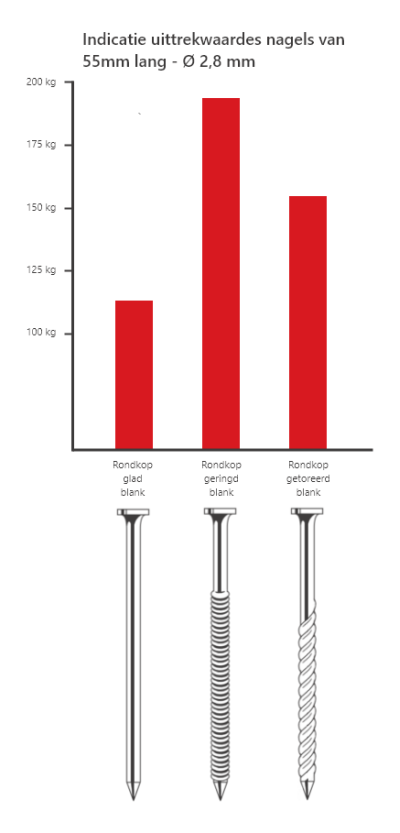

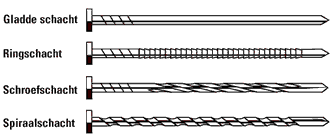

The shank is the part of the nail that provides almost all the bonding force. The shaft is forced between the wood fibers, whereby the fibers press against the shaft. This pressure makes it difficult to pull the nail out of the wood. The shaft of the nail can be smooth, spiral, ringed or screwed. The shape of the shank also largely determines how much adhesive power the nail has. Nails with ring shanks and screw shanks have the best pull-out value. Ring shanks are often used for shorter nails and with longer nails it is easy to drive the nail into the material due to the tapped finish.

Properties of the different dishes:

- Smooth shank: Easier to make than nails with a relief in the shank. In addition, they require less impact force to drive the nail into the material. However, due to their smooth shaft, they also have less adhesive power

- Ring shaft: provided with a ring relief on their shaft. The different diameters in the nail ensure that they have a greater adhesive force than nails with a smooth shank. However, more impact force is also required to attach these nails

- Screw shaft: These have a tapped finish. The wood fibers wrap around the deformed shaft and the different diameters of the shaft provide greater adhesion

- Spiral shaft: Made of square metal wire, they are twisted during production. They are relatively cheap to make and have a better pullout value than smooth shank nails. They do, however, have less good adhesion than nails with ring shanks or screw shanks

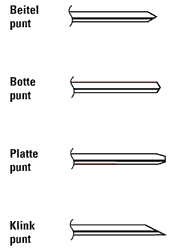

Point

The point of a nail is more important than you might initially suspect. By default, nails have a chisel point. This is quite sharp and allows the nail to penetrate the wood easily. In addition, there are also special nail points, each with its own function. For example, blunt or flat points are used to prevent the wood from splitting. There is also a riveting point, using a nail with this point causes it to bend when you drive it into the material. This will give you a kind of cramp. These nails are also called cling nails.

Buy nails on a strip?

Need strip nails? At Tackershop we can supply many different nails on strips. Do you have questions? We are happy to help you! Please feel free to contact us via the contact form on the website or send an email to info@bestfix.nl. For direct contact, please call +31 (0)570 768 737< /strong>.